Ladders are one of the leading sources of workplace injury. The Centers for Disease Control (CDC) report 8-in-10 construction injuries treated in emergency rooms nationwide involve ladders. Most ladder injuries are the result of falls. Either a worker loses balance and falls off a ladder, or it’s unstable and tips over with a worker on it. Another big injury risk is electrocution when working near power lines. Your employees are at risk of ladder injuries each time they set foot on one. However, most of those injuries are preventable.

What your employees need to know about safe ladder use

Ladders are not always the safest option. Sometimes scaffolding or aerial lifts are safer. Once it’s determined that the ladder is the best option for the job it’s important to use the right one. The right ladder for the job may not be the first one available or easiest to carry.

If power lines are nearby, trade the aluminum ladder for a non-conductive one with wooden or fiberglass sides. When an aluminum ladder makes contact with live power lines, it immediately energizes and puts workers at risk of electrocution.

What your employees need to do to use a ladder safely

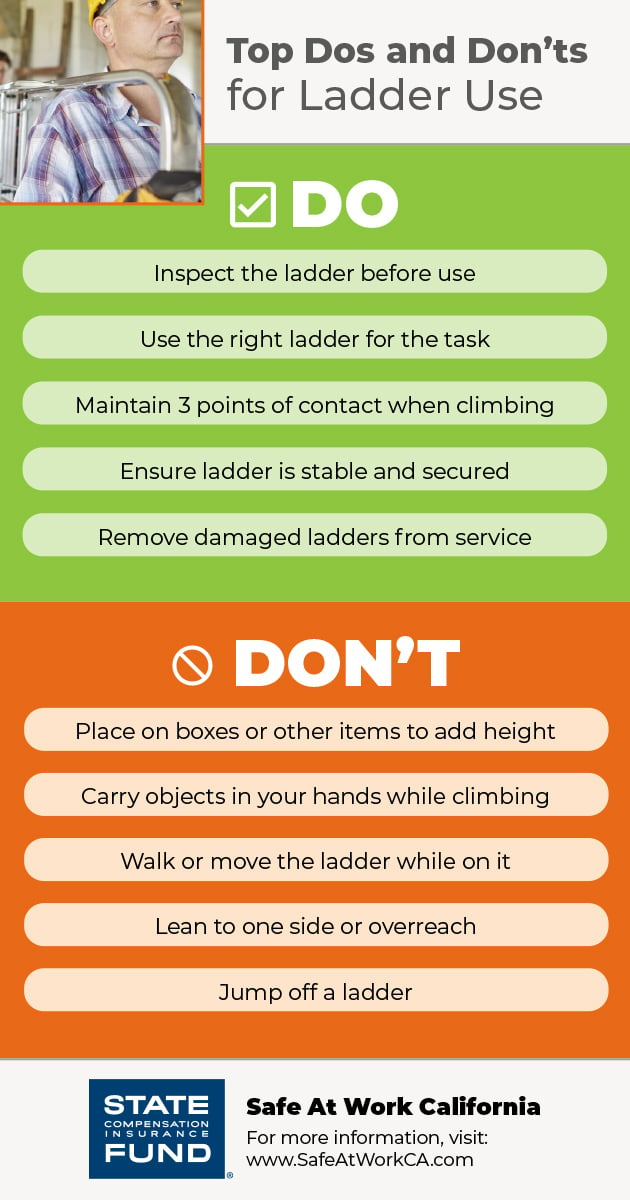

After choosing the right ladder, inspect it to make sure it’s in good working condition. If the inspection shows any defects, take the ladder out of service and tag it as damaged.

When putting the ladder in place, follow these three important rules:

- If using an extension ladder, extend the ladder three feet above the landing—the 3-foot rule.

- Move the base of the ladder out one foot for every four feet of ladder height—the 4-to-1 rule.

- Ladders shall be tied, blocked, or otherwise secured against movement or slippage.

When climbing a ladder, always maintain three points of contact. Use a tool belt to carry tools up the ladder, rather than holding anything in your hands.

Keep the area around the top and base of the ladder clear. Avoid running hoses, extension cords, or ropes on a ladder as these may cause obstructions.

Do not lean to one side on the ladder. If something is out of reach, climb down and move the ladder to the right spot. Also, never tie ladders together or place on boxes, buckets, or other objects to get extra height.

What to cover at your safety meeting on ladder use

Since each worksite is different, begin your safety meeting by addressing issues specific to that location. Identify any power lines, the condition of the ground, and tight spaces.

Demonstrate how to inspect a ladder:

- Check for loose steps and rungs

- Check for any slippery material like oil and grease

- Check the steps or rungs for cracks, splits, and bent edges

- Check that fasteners (bolts, screws, etc.) are tight and secure

- Check the ladder feet and non-slip base for damage

Review your process for taking damaged ladders out of service. This includes tagging, storage, and possible disposal.

Make sure your employees understand and use both the 3-foot rule and the 4-to-1 rule.

Demonstrate how to move a ladder. Remind employees to collapse it to its shortest possible length and have someone help move it.

Show your employees how to maintain three points of contact when climbing or descending a ladder, with either one hand and two feet or two hands and one foot—and remind them to face the ladder when climbing up or down. Also, remind them to use a tool belt and never carry anything in their hands.

Let your employees know most ladder injuries are preventable. Talk about the importance of ladder safety. Print and post the do's and don'ts in a common area as a reminder.

(Rev. 1/2024)